Carbon Dioxide Pumps

Reliability, quality, and function are what

makes our custom units so special.

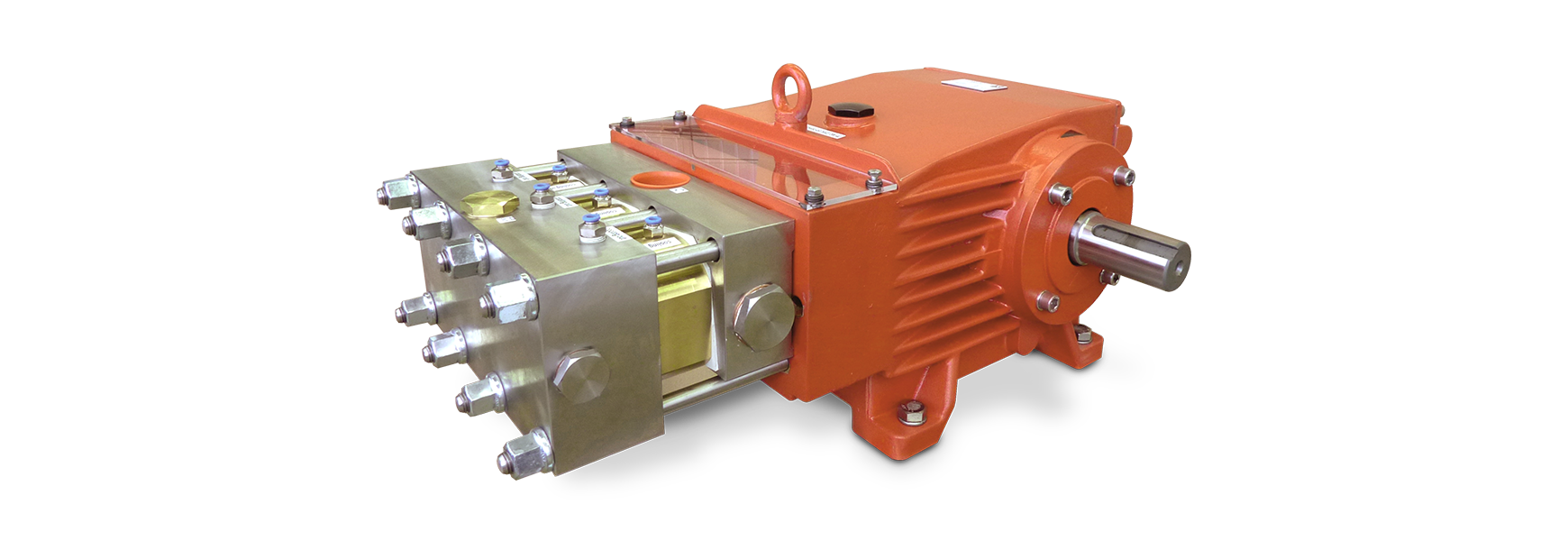

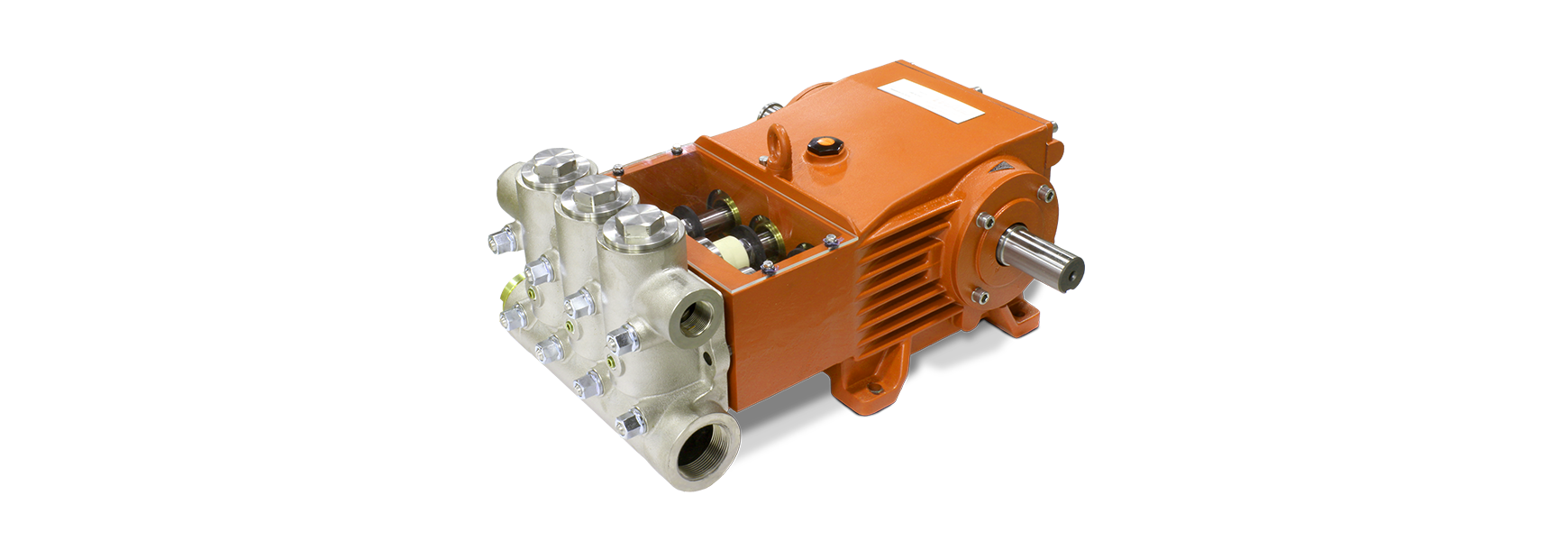

Supercritical Circulation Pump

When you need a pump that requires CO2 to be circulated under high pressure— such as extraction and impregnation—this is the unit to turn to. For these types of supercritical applications, this model can pump CO2 up to 4350 PSI (300 bar), and can also circulate CO2 in this pressure range (i.e., an inlet and discharge pressure of up to 4350 PSI [300 bar] at 0 to 13.5 GPM [0 to 51 L/min]). With a small dead-space ratio, this pump allows CO2 to be pumped at large pressure ratios in the supercritical or elastic range. This model is a real workhorse. It is equipped with five cooling circuits that allow frictional heat from the seals to be carried away and to keep the CO2 in the suction channel from overheating.

Another key feature of this pump is its ability to liquefy gaseous CO2 to restart the pump once it has been stopped. And because it has compact, closed seals and valves, servicing is quicker and more streamlined. Plus, this pump has an optional grease-lubricated drive fitted with antifriction bearings, which allows for a control range of 0 to 100 percent, along with oil-free operation.

Features include first-rate materials such as stainless-steel valve casings, a hard-metal-coated stainless-steel plunger, high-grade stainless-steel valves, Teflon or Aramid packing seals and a drop-forged, case-hardened crankshaft.

| Pump Model | Maximum Volume | Maximum Discharge Pressure | Speed | ||

| GPM | LPM | PSI | bar | RPM | |

| CLP124C (Oil) | 13.5 | 51 | 4350 | 300 | 1000 |

| CLP124G (Grease) | 13.5 | 51 | 4350 | 300 | 1000 |

Materials

| Valve Casing | Stainless Steel AISI 303 |  |

| Plunger | Hard Metal Coated Stainless Steel | |

| Valves | High-Grade Stainless Steel | |

| HP Seals | Teflon or Aramid Packing | |

| Crankshaft | Drop Forged and Case Hardened | |

| space | space | |

| space | space | |

| space | space |

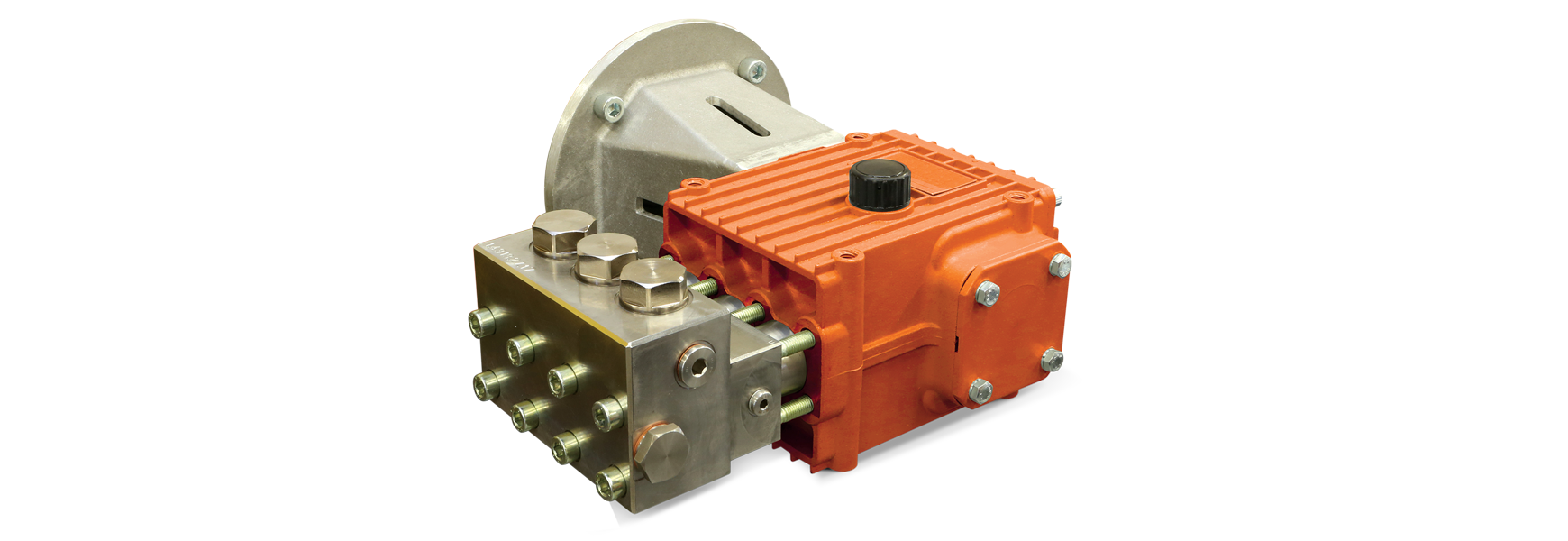

CO2 Liquid and Gaseous Pump Compressor

ECO2Blast’s pump compressor can pump gaseous CO2 from vessels back to a storage container. The pressure in the storage container is reduced to approximately ambient pressure, and any remaining CO2 in the vessel is not lost to the surroundings.

The cooled cylinders on this unit prolong the life of the piston seals. The cooled discharge casing also reduces the outlet temperature. The pump compressor is designed to pump gaseous and liquid CO2 at less than 72.5 PSI (5 bar) in the liquid phase against the tank pressure at a maximum discharge pressure of 1160 (80 bar), which means it’s as efficient as conventional oil-lubricated compressors and far more efficient than centrifugal pumps.

The Liquid and Gaseous Pump Compressor is the answer for applications where heat is a factor. A variance of as little as a single degree can cause liquid CO2 to turn into a gas. This pump compressor can handle both liquid and gas CO2. ECO2Blast is developing this technology in other pumps as well.

| Pump Model | Maximum Volume | Maximum Discharge Pressure | Speed | ||

| GPM | LPM | PSI | bar | RPM | |

| CGP7163 | 59.3 | 224.4 | 1160 | 80 | 480 |

High Inlet Pressure Pump

This pump has a 303 stainless-steel manifold that can handle inlet pressure up to 1200 PSI (83 bar). These are triplex-plunger, positive-displacement pumps that have reciprocating plungers. Other features include an aluminum crankcase with sight glass and a vented dipstick; a forged, through-hardened, ground and polished crankshaft; bronze connecting rods; hardened stainless-steel plunger bases; solid ceramic plungers; Teflon/Nitrile seals with EPDM O-rings; stainless-steel valves.

| Pump Model | Maximum Volume | Maximum Discharge Pressure | Speed | ||

| GPM | LPM | PSI | bar | RPM | |

| CP460-4053 | 1.6 | 6.2 | 6000 | 415 | 750 |

Other CO2 Pumps

Other ECO2Blast’s pumps are available in numerous models that operate up to a maximum volume of 51.7 GPM (196.0 L/min), with a maximum discharge pressure of 2000 PSI (140 bar), and at speeds up to 750 RPM. These powerful pumps are built to precise engineering standards.

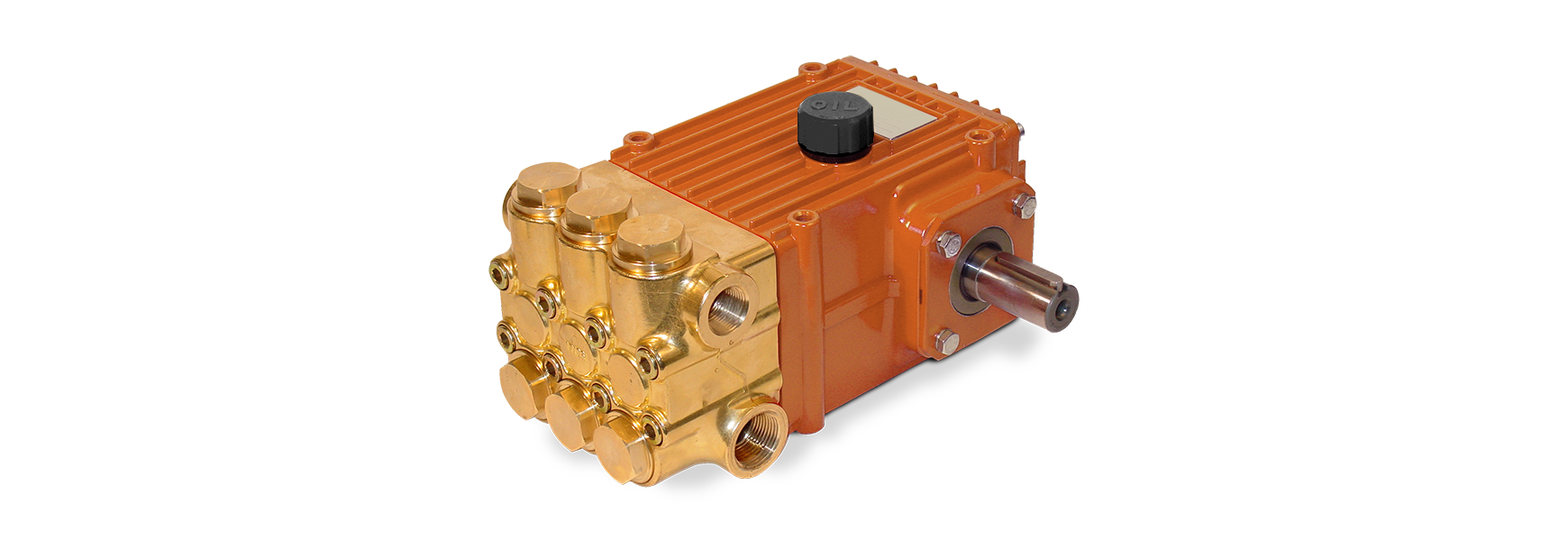

CP200 and CP400 Series

These are triplex-plunger, positive-displacement pumps that have reciprocating plungers. Other features include an aluminum crankcase with sight glass and a vented dipstick; a forged, through-hardened, ground and polished crankshaft; bronze connecting rods; hardened stainless-steel plunger bases; solid ceramic plungers; Teflon/Nitrile seals with EPDM O-rings; stainless-steel valves; and a forged-brass manifold.

Options Include:

• Stainless Steel Manifold

• Bell Housing / Pump Flange

• Drive Coupling

| Pump Model | Maximum Volume | Maximum Discharge Pressure | Speed | ||

| GPM | LPM | PSI | bar | RPM | |

| CP230 | 0.5 | 1.8 | 2030 | 140 | 750 |

| CP217 | 0.73 | 2.7 | 2030 | 140 | 750 |

| CP218 | 1.4 | 5.3 | 2030 | 140 | 750 |

| CP220 | 1.9 | 7.3 | 2030 | 140 | 750 |

| CP425 | 5.5 | 21.0 | 2030 | 140 | 750 |

| CP420 | 6.4 | 24.3 | 1740 | 120 | 750 |

| CP470 | 9.2 | 35.0 | 1740 | 120 | 750 |

Large Volume Pumps

These models feature a reciprocating triplex plunger pump for liquid CO2 applications. Other features include a spheroid cast-iron crankcase with sight glass and a vented dipstick; a forged, through-hardened, ground and polished crankshaft; bronze connecting rods; hardened stainless steel plunger bases; solid ceramic plungers; Teflon/Nitrile seals with EPDM O-rings; stainless-steel valves.

• The CLP121A has a cast-aluminum bronze manifold

• The CLP121A-4000 has a 303 stainless-steel manifold

• The CGP7255A has a nickel-plated cast-iron manifold

| Pump Model | Maximum Volume | Maximum Discharge Pressure | Speed | ||

| GPM | LPM | PSI | bar | RPM | |

| CLP121A | 16.3 | 61.6 | 1740 | 120 | 500 |

| CLP121A-4000 | 16.3 | 61.6 | 1740 | 120 | 500 |

| CGP7255A | 51.7 | 196 | 1450 | 100 | 550 |